Value-added recycling for compliance through to the labor market

Geisenheim / Ortenberg, 29. August 2023 – While waste separation and recycling are mandatory and standard in the private sector, the situation is often different in industry: “Plastic waste, offcuts and old material generated in companies are often not recycled but disposed of. Together with many partners, we are working to change this permanently and make recycling the standard also in the plastics industry,” says Heiko Pfister, Managing Director of Pekutherm. The company, based in Geisenheim am Rhein, specializes in the recycling of special transparent plastics such as acrylic glass (PMMA), PC (polycarbonate) and PETG.

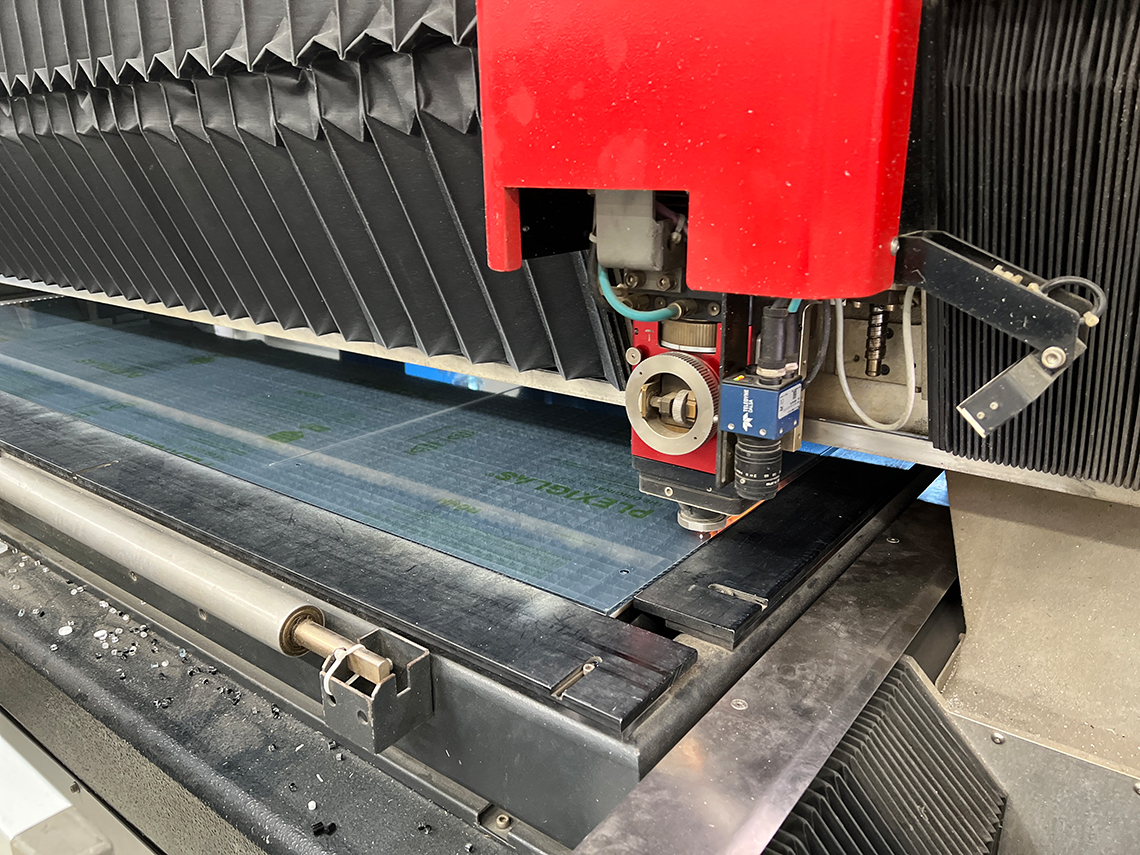

One example shows the potential of recycling: Schäfer Kunststofftechnik GmbH from Ortenberg, a plastics processor, was able to return 89 tons of material to the cycle last year, saving over 400 tons of CO2 in the process. The medium-sized company with around 100 employees develops and produces high-quality products from semi-finished plastic products, primarily complex machine cladding for mechanical engineering and precision parts for laboratory and medical technology made from acrylic glass and other plastics. Schäfer processes over 400 tons of raw material per year, 320 tons of which is PMMA alone.

Offcuts are worth their weight in gold

Schäfer Kunststofftechnik collects all waste – offcuts, unused material and old material – in the Ecobox provided by Pekutherm. The foldable and space-saving collection container was developed by Pekutherm and is also available to other plastics processors. The holistic and seamlessly integrated concept also takes care of the logistics of the Ecoboxes. As a certified waste management company, Pekutherm produces sorted recyclates from the plastic waste produced – the waste is not exported.

“As a company, we are aware of the urgent need to reduce our resource consumption and further minimize our ecological footprint. We are proud to make an active contribution to environmental protection by recycling plastic waste and to be committed to a sustainable future,” explains Joachim Schäfer, Managing Director of Schäfer Kunststofftechnik, who has been working with Pekutherm in the field of plastics recycling for many years. And the offcuts also have value: the amount produced is remunerated in line with current raw material prices instead of having to be written off completely on disposal or even generating additional costs.

Sustainability is required

Sustainability is becoming increasingly important in more and more industries: compliance requirements, for example, only permit business relationships with companies with proven environmental protection activities. Pekutherm issues a recycling certificate that not only shows

the amount of material collected, but also the amount of CO2 spared for the environment. With this certificate, companies can also demonstrate their environmental friendliness to the outside world. For Schäfer Kunststofftechnik alone, this amounts to over 400 tons of CO2 – extrapolated to the whole of Germany, the recycling concept developed by Pekutherm can save many thousands of tons of CO2. “We process PMMA, PC or PETG waste into pure and sorted recyclates that are reprocessed into high-quality and durable products in the plastics industry. There is no down-cycling, no export of plastic waste, but new products are created, including visually sophisticated products such as displays, lamps or carport covers, to name just a few examples,” explains Heiko Pfister from Pekutherm.

PR-Agentur: euromarcom public relations GmbH,

Mühlhohle 2, 65205 Wiesbaden, Deutschland,

Tel.: +49 611 973150, E-Mail: team@euromarcom.de,

Web: www.euromarcom.de